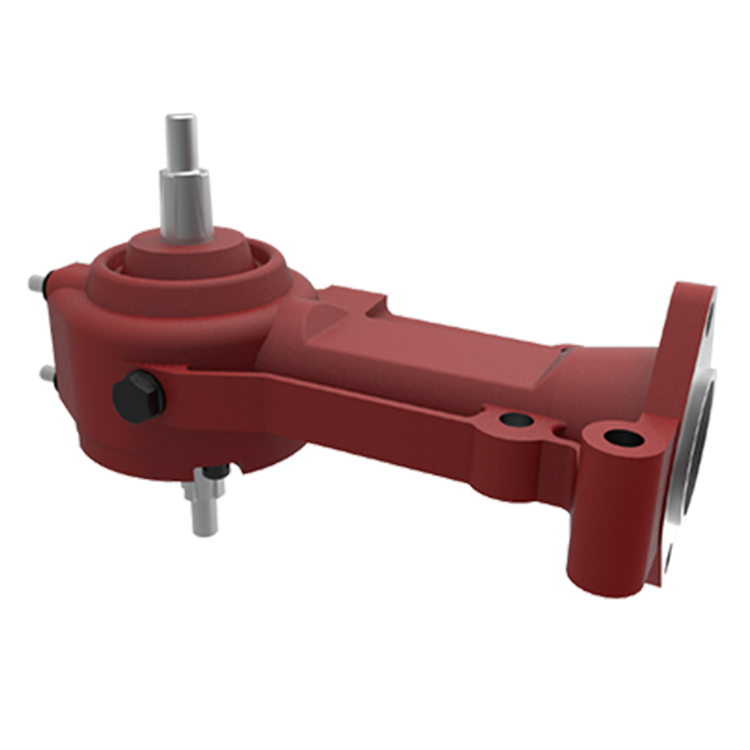

Product Description

Transmission Shaft PTO Shaft for Agricultural Machine

Durable Transmission Shaft Made of aluminum alloy with excellent quality and carefully selected materials,the hot head greatly extends its service life.

Application Scope for PTO Shafts

Various types of agricultural machinery transmission shafts, with a wide range of product uses, which are mainly suitable for agricultural tractors,micro tillers,rotary tillers,seeders,fertilizer spreaders,lawn mowers,baling machines,grass bales and so on.

| Series | D(mm) | W(mm) | 540 | 1000 | ||||

| CV | KW | NM | CV | KW | NM | |||

| 1S | 22.0 | 54.0 | 16 | 12 | 210 | 25 | 18 | 172 |

| 2S | 23.8 | 61.3 | 21 | 15 | 270 | 31 | 23 | 220 |

| 3S | 27.0 | 70.0 | 30 | 22 | 390 | 47 | 35 | 330 |

| 4S | 27.0 | 74.6 | 35 | 26 | 460 | 55 | 40 | 380 |

| 5S | 30.2 | 80.0 | 47 | 35 | 620 | 74 | 54 | 520 |

| 6S | 30.2 | 92.0 | 64 | 47 | 830 | 100 | 74 | 710 |

| 7S | 30.2 | 106.5 | 75 | 55 | 970 | 118 | 87 | 830 |

| 8S | 35.0 | 106.5 | 95 | 70 | 1240 | 150 | 110 | 1050 |

| 9S | 41.0 | 108.0 | 120 | 88 | 1560 | 190 | 140 | 1340 |

Company Profile

Shuoxin, Sure thing.

ZheJiang Shuoxin Machinery Manufacturing Co., Ltd has been in the agricultural machinery industry for more than 30 years, the product range covering spraying machines, fertilizer spreaders, manure spreaders, mowers, rakes, land levellers and so on. In the 30 years’ service for agriculture field, Shuoxin has grown into an enterprise that integrates multiple business modules such as Design, Manufacture, Service and Information Survey. Shuoxin agricultural machinery have done a important work to nutrition supply and plant diseases & insect pests control for crops such as wheat, cotton, corn, rice, orchards and vegetables. With the ISO System certificates and CE production certificates, Cooperating with Shuixin can guarantee the partners with advanced machine products, reduced labor cost, improved work efficiency and promoted product revenue.

Certifications

Product packaging

Iron Farme Packing

All the machines are fixed in the Iron Frame by steel wire, the Frame use the steel which is thicker than 3mm. Strong enough to carry and protect the machine.

Black plastic film will also protect the machine from rain and sun shine.

All the frames is welded according to the machine size, to make sure the minimum size and weight.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Shaft |

|---|---|

| Usage: | Tillage, Harvester, Planting and Fertilization |

| Material: | Iron |

| Power Source: | Tractor |

| Weight: | 6kg |

| After-sales Service: | Online Service |

| Customization: |

Available

| Customized Request |

|---|

Can drive shafts be adapted for use in both automotive and industrial settings?

Yes, drive shafts can be adapted for use in both automotive and industrial settings. While there may be some differences in design and specifications based on the specific application requirements, the fundamental principles and functions of drive shafts remain applicable in both contexts. Here’s a detailed explanation:

1. Power Transmission:

Drive shafts serve the primary purpose of transmitting rotational power from a power source, such as an engine or motor, to driven components, which can be wheels, machinery, or other mechanical systems. This fundamental function applies to both automotive and industrial settings. Whether it’s delivering power to the wheels of a vehicle or transferring torque to industrial machinery, the basic principle of power transmission remains the same for drive shafts in both contexts.

2. Design Considerations:

While there may be variations in design based on specific applications, the core design considerations for drive shafts are similar in both automotive and industrial settings. Factors such as torque requirements, operating speeds, length, and material selection are taken into account in both cases. Automotive drive shafts are typically designed to accommodate the dynamic nature of vehicle operation, including variations in speed, angles, and suspension movement. Industrial drive shafts, on the other hand, may be designed for specific machinery and equipment, taking into consideration factors such as load capacity, operating conditions, and alignment requirements. However, the underlying principles of ensuring proper dimensions, strength, and balance are essential in both automotive and industrial drive shaft designs.

3. Material Selection:

The material selection for drive shafts is influenced by the specific requirements of the application, whether in automotive or industrial settings. In automotive applications, drive shafts are commonly made from materials such as steel or aluminum alloys, chosen for their strength, durability, and ability to withstand varying operating conditions. In industrial settings, drive shafts may be made from a broader range of materials, including steel, stainless steel, or even specialized alloys, depending on factors such as load capacity, corrosion resistance, or temperature tolerance. The material selection is tailored to meet the specific needs of the application while ensuring efficient power transfer and durability.

4. Joint Configurations:

Both automotive and industrial drive shafts may incorporate various joint configurations to accommodate the specific requirements of the application. Universal joints (U-joints) are commonly used in both contexts to allow for angular movement and compensate for misalignment between the drive shaft and driven components. Constant velocity (CV) joints are also utilized, particularly in automotive drive shafts, to maintain a constant velocity of rotation and accommodate varying operating angles. These joint configurations are adapted and optimized based on the specific needs of automotive or industrial applications.

5. Maintenance and Service:

While maintenance practices may vary between automotive and industrial settings, the importance of regular inspection, lubrication, and balancing remains crucial in both cases. Both automotive and industrial drive shafts benefit from periodic maintenance to ensure optimal performance, identify potential issues, and prolong the lifespan of the drive shafts. Lubrication of joints, inspection for wear or damage, and balancing procedures are common maintenance tasks for drive shafts in both automotive and industrial applications.

6. Customization and Adaptation:

Drive shafts can be customized and adapted to meet the specific requirements of various automotive and industrial applications. Manufacturers often offer drive shafts with different lengths, diameters, and joint configurations to accommodate a wide range of vehicles or machinery. This flexibility allows for the adaptation of drive shafts to suit the specific torque, speed, and dimensional requirements of different applications, whether in automotive or industrial settings.

In summary, drive shafts can be adapted for use in both automotive and industrial settings by considering the specific requirements of each application. While there may be variations in design, materials, joint configurations, and maintenance practices, the fundamental principles of power transmission, design considerations, and customization options remain applicable in both contexts. Drive shafts play a crucial role in both automotive and industrial applications, enabling efficient power transfer and reliable operation in a wide range of mechanical systems.

Can you provide real-world examples of vehicles and machinery that use drive shafts?

Drive shafts are widely used in various vehicles and machinery to transmit power from the engine or power source to the wheels or driven components. Here are some real-world examples of vehicles and machinery that utilize drive shafts:

1. Automobiles:

Drive shafts are commonly found in automobiles, especially those with rear-wheel drive or four-wheel drive systems. In these vehicles, the drive shaft transfers power from the transmission or transfer case to the rear differential or front differential, respectively. This allows the engine’s power to be distributed to the wheels, propelling the vehicle forward.

2. Trucks and Commercial Vehicles:

Drive shafts are essential components in trucks and commercial vehicles. They are used to transfer power from the transmission or transfer case to the rear axle or multiple axles in the case of heavy-duty trucks. Drive shafts in commercial vehicles are designed to handle higher torque loads and are often larger and more robust than those used in passenger cars.

3. Construction and Earthmoving Equipment:

Various types of construction and earthmoving equipment, such as excavators, loaders, bulldozers, and graders, rely on drive shafts for power transmission. These machines typically have complex drivetrain systems that use drive shafts to transfer power from the engine to the wheels or tracks, enabling them to perform heavy-duty tasks on construction sites or in mining operations.

4. Agricultural Machinery:

Agricultural machinery, including tractors, combines, and harvesters, utilize drive shafts to transmit power from the engine to the wheels or driven components. Drive shafts in agricultural machinery are often subjected to demanding conditions and may have additional features such as telescopic sections to accommodate variable distances between components.

5. Industrial Machinery:

Industrial machinery, such as manufacturing equipment, generators, pumps, and compressors, often incorporate drive shafts in their power transmission systems. These drive shafts transfer power from electric motors, engines, or other power sources to various driven components, enabling the machinery to perform specific tasks in industrial settings.

6. Marine Vessels:

In marine applications, drive shafts are commonly used to transmit power from the engine to the propeller in boats, ships, and other watercraft. Marine drive shafts are typically longer and designed to withstand the unique challenges posed by water environments, including corrosion resistance and appropriate sealing mechanisms.

7. Recreational Vehicles (RVs) and Motorhomes:

RVs and motorhomes often employ drive shafts as part of their drivetrain systems. These drive shafts transfer power from the transmission to the rear axle, allowing the vehicle to move and providing propulsion. Drive shafts in RVs may have additional features such as dampers or vibration-reducing components to enhance comfort during travel.

8. Off-Road and Racing Vehicles:

Off-road vehicles, such as SUVs, trucks, and all-terrain vehicles (ATVs), as well as racing vehicles, frequently utilize drive shafts. These drive shafts are designed to withstand the rigors of off-road conditions or high-performance racing, transmitting power efficiently to the wheels and ensuring optimal traction and performance.

9. Railway Rolling Stock:

In railway systems, drive shafts are employed in locomotives and some types of rolling stock. They transfer power from the locomotive’s engine to the wheels or propulsion system, enabling the train to move along the tracks. Railway drive shafts are typically much longer and may have additional features to accommodate the articulated or flexible nature of some train configurations.

10. Wind Turbines:

Large-scale wind turbines used for generating electricity incorporate drive shafts in their power transmission systems. The drive shafts transfer rotational energy from the turbine’s blades to the generator, where it is converted into electrical power. Drive shafts in wind turbines are designed to handle the significant torque and rotational forces generated by the wind.

These examples demonstrate the broad range of vehicles and machinery that rely on drive shafts for efficient power transmission and propulsion. Drive shafts are essential components in various industries, enabling the transfer of power from the source to the driven components, ultimately facilitating movement, operation, or the performance of specific tasks.

Can you explain the different types of drive shafts and their specific applications?

Drive shafts come in various types, each designed to suit specific applications and requirements. The choice of drive shaft depends on factors such as the type of vehicle or equipment, power transmission needs, space limitations, and operating conditions. Here’s an explanation of the different types of drive shafts and their specific applications:

1. Solid Shaft:

A solid shaft, also known as a one-piece or solid-steel drive shaft, is a single, uninterrupted shaft that runs from the engine or power source to the driven components. It is a simple and robust design used in many applications. Solid shafts are commonly found in rear-wheel-drive vehicles, where they transmit power from the transmission to the rear axle. They are also used in industrial machinery, such as pumps, generators, and conveyors, where a straight and rigid power transmission is required.

2. Tubular Shaft:

Tubular shafts, also called hollow shafts, are drive shafts with a cylindrical tube-like structure. They are constructed with a hollow core and are typically lighter than solid shafts. Tubular shafts offer benefits such as reduced weight, improved torsional stiffness, and better damping of vibrations. They find applications in various vehicles, including cars, trucks, and motorcycles, as well as in industrial equipment and machinery. Tubular drive shafts are commonly used in front-wheel-drive vehicles, where they connect the transmission to the front wheels.

3. Constant Velocity (CV) Shaft:

Constant Velocity (CV) shafts are specifically designed to handle angular movement and maintain a constant velocity between the engine/transmission and the driven components. They incorporate CV joints at both ends, which allow flexibility and compensation for changes in angle. CV shafts are commonly used in front-wheel-drive and all-wheel-drive vehicles, as well as in off-road vehicles and certain heavy machinery. The CV joints enable smooth power transmission even when the wheels are turned or the suspension moves, reducing vibrations and improving overall performance.

4. Slip Joint Shaft:

Slip joint shafts, also known as telescopic shafts, consist of two or more tubular sections that can slide in and out of each other. This design allows for length adjustment, accommodating changes in distance between the engine/transmission and the driven components. Slip joint shafts are commonly used in vehicles with long wheelbases or adjustable suspension systems, such as some trucks, buses, and recreational vehicles. By providing flexibility in length, slip joint shafts ensure a constant power transfer, even when the vehicle chassis experiences movement or changes in suspension geometry.

5. Double Cardan Shaft:

A double Cardan shaft, also referred to as a double universal joint shaft, is a type of drive shaft that incorporates two universal joints. This configuration helps to reduce vibrations and minimize the operating angles of the joints, resulting in smoother power transmission. Double Cardan shafts are commonly used in heavy-duty applications, such as trucks, off-road vehicles, and agricultural machinery. They are particularly suitable for applications with high torque requirements and large operating angles, providing enhanced durability and performance.

6. Composite Shaft:

Composite shafts are made from composite materials such as carbon fiber or fiberglass, offering advantages such as reduced weight, improved strength, and resistance to corrosion. Composite drive shafts are increasingly being used in high-performance vehicles, sports cars, and racing applications, where weight reduction and enhanced power-to-weight ratio are critical. The composite construction allows for precise tuning of stiffness and damping characteristics, resulting in improved vehicle dynamics and drivetrain efficiency.

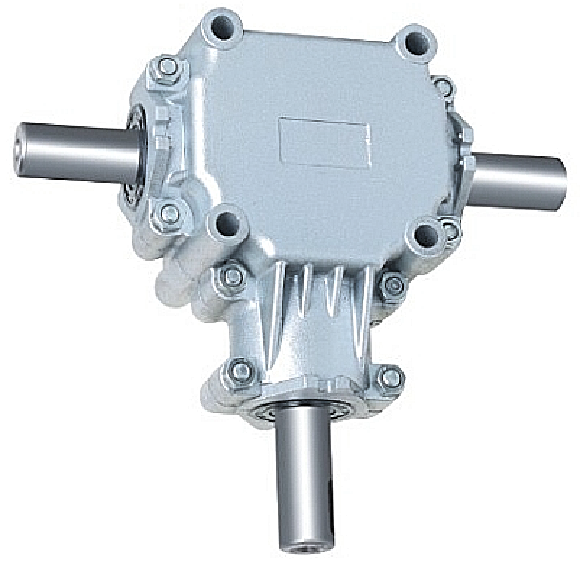

7. PTO Shaft:

Power Take-Off (PTO) shafts are specialized drive shafts used in agricultural machinery and certain industrial equipment. They are designed to transfer power from the engine or power source to various attachments, such as mowers, balers, or pumps. PTO shafts typically have a splined connection at one end to connect to the power source and a universal joint at the other end to accommodate angular movement. They are characterized by their ability to transmit high torque levels and their compatibility with a range of driven implements.

8. Marine Shaft:

Marine shafts, also known as propeller shafts or tail shafts, are specifically designed for marine vessels. They transmit power from the engine to the propeller, enabling propulsion. Marine shafts are usually long and operate in a harsh environment, exposed to water, corrosion, and high torque loads. They are typically made of stainless steel or other corrosion-resistant materials and are designed to withstand the challenging conditions encountered in marine applications.

It’simportant to note that the specific applications of drive shafts may vary depending on the vehicle or equipment manufacturer, as well as the specific design and engineering requirements. The examples provided above highlight common applications for each type of drive shaft, but there may be additional variations and specialized designs based on specific industry needs and technological advancements.

editor by CX 2024-05-09

China manufacturer Back Pack Brush Cutter Drive Shaft for Grass Trimmergasoline Backpack Blade Parts Tractor 43cc Machine

Product Description

Product Description

Product Description

Specification:

| Model no.: HY430 | |

| Power type: | Two-stroke,Single Cylinder,Air-cooling |

| Displacement: | 43cc / 52cc. |

| Max power: | 1.70 / 1.85 KW |

| Engine: | 1E40F-5 / 1E44F-5 |

| Starter: | sginle/ easy starter |

| Two-cycle oil/Gasoline Mixing Ratio: | 1 : 25 |

| Start system: | Recoil |

| Ignition: | CDI |

| Carburetor: | Pump-film type |

| Fuel tank capacity: | 1.2 L |

| Idle speed: | 2800-3400rpm |

| Clutch speed: | 4500–5000rpm |

| Max speed: | 8500-9500rpm |

| Package: | Engine+ Shaft seperatly |

| N. W. /G. W.: | 8.7/10.1kgs |

| 20GP / 40GP / 40HQ: | 1571PCS / 2130PCS / 2500PCS |

| Color | Any 1 is ok. |

Brush cutter HY430

Mating Power: 40F-5, 44F-5

Products Recommended

Company Profile

Packaging & Shipping

FAQ

Q: 1. You are trading company or Manufacturer?

We are a reliable manufacturer of gasoline brush cutterschain saws over 10 years.

Q: 2. What about your payment terms?

T/T at sight. 30% deposit,the balance against BL copy

Q: 3. What’s your delivery time?

About 40-45days after get deposit and order details confirmed

Q: 4. What’s your biggest advantage?

The goods fantastic performance.Competitive pricegood quality and customizable service.OEM is available

Q: 5. Can you supply us sample for testing?

Yes, of course.Buy from our local customer or made for you,1 pcs within 3days finished. by DHL 3working days

Q: 6. Do you supply after-sale service?

Yes, of course.Send us any feedback immediately,with photos or videos is much better. benefit to improving and service you and your customers better.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Usage: | Grass, Shrub |

|---|---|

| Feature: | 2-Stroke, Single Cylinder, High Torque, Folding Handle |

| Cutter: | Straight Metal Blade |

| Applicable Area: | 1000-5000m² |

| Certification: | CE |

| Type: | Hanging Brush Cutter |

| Samples: |

US$ 37/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can drive shafts be adapted for use in both automotive and industrial settings?

Yes, drive shafts can be adapted for use in both automotive and industrial settings. While there may be some differences in design and specifications based on the specific application requirements, the fundamental principles and functions of drive shafts remain applicable in both contexts. Here’s a detailed explanation:

1. Power Transmission:

Drive shafts serve the primary purpose of transmitting rotational power from a power source, such as an engine or motor, to driven components, which can be wheels, machinery, or other mechanical systems. This fundamental function applies to both automotive and industrial settings. Whether it’s delivering power to the wheels of a vehicle or transferring torque to industrial machinery, the basic principle of power transmission remains the same for drive shafts in both contexts.

2. Design Considerations:

While there may be variations in design based on specific applications, the core design considerations for drive shafts are similar in both automotive and industrial settings. Factors such as torque requirements, operating speeds, length, and material selection are taken into account in both cases. Automotive drive shafts are typically designed to accommodate the dynamic nature of vehicle operation, including variations in speed, angles, and suspension movement. Industrial drive shafts, on the other hand, may be designed for specific machinery and equipment, taking into consideration factors such as load capacity, operating conditions, and alignment requirements. However, the underlying principles of ensuring proper dimensions, strength, and balance are essential in both automotive and industrial drive shaft designs.

3. Material Selection:

The material selection for drive shafts is influenced by the specific requirements of the application, whether in automotive or industrial settings. In automotive applications, drive shafts are commonly made from materials such as steel or aluminum alloys, chosen for their strength, durability, and ability to withstand varying operating conditions. In industrial settings, drive shafts may be made from a broader range of materials, including steel, stainless steel, or even specialized alloys, depending on factors such as load capacity, corrosion resistance, or temperature tolerance. The material selection is tailored to meet the specific needs of the application while ensuring efficient power transfer and durability.

4. Joint Configurations:

Both automotive and industrial drive shafts may incorporate various joint configurations to accommodate the specific requirements of the application. Universal joints (U-joints) are commonly used in both contexts to allow for angular movement and compensate for misalignment between the drive shaft and driven components. Constant velocity (CV) joints are also utilized, particularly in automotive drive shafts, to maintain a constant velocity of rotation and accommodate varying operating angles. These joint configurations are adapted and optimized based on the specific needs of automotive or industrial applications.

5. Maintenance and Service:

While maintenance practices may vary between automotive and industrial settings, the importance of regular inspection, lubrication, and balancing remains crucial in both cases. Both automotive and industrial drive shafts benefit from periodic maintenance to ensure optimal performance, identify potential issues, and prolong the lifespan of the drive shafts. Lubrication of joints, inspection for wear or damage, and balancing procedures are common maintenance tasks for drive shafts in both automotive and industrial applications.

6. Customization and Adaptation:

Drive shafts can be customized and adapted to meet the specific requirements of various automotive and industrial applications. Manufacturers often offer drive shafts with different lengths, diameters, and joint configurations to accommodate a wide range of vehicles or machinery. This flexibility allows for the adaptation of drive shafts to suit the specific torque, speed, and dimensional requirements of different applications, whether in automotive or industrial settings.

In summary, drive shafts can be adapted for use in both automotive and industrial settings by considering the specific requirements of each application. While there may be variations in design, materials, joint configurations, and maintenance practices, the fundamental principles of power transmission, design considerations, and customization options remain applicable in both contexts. Drive shafts play a crucial role in both automotive and industrial applications, enabling efficient power transfer and reliable operation in a wide range of mechanical systems.

How do drive shafts contribute to the efficiency of vehicle propulsion and power transmission?

Drive shafts play a crucial role in the efficiency of vehicle propulsion and power transmission systems. They are responsible for transferring power from the engine or power source to the wheels or driven components. Here’s a detailed explanation of how drive shafts contribute to the efficiency of vehicle propulsion and power transmission:

1. Power Transfer:

Drive shafts transmit power from the engine or power source to the wheels or driven components. By efficiently transferring rotational energy, drive shafts enable the vehicle to move forward or drive the machinery. The design and construction of drive shafts ensure minimal power loss during the transfer process, maximizing the efficiency of power transmission.

2. Torque Conversion:

Drive shafts can convert torque from the engine or power source to the wheels or driven components. Torque conversion is necessary to match the power characteristics of the engine with the requirements of the vehicle or machinery. Drive shafts with appropriate torque conversion capabilities ensure that the power delivered to the wheels is optimized for efficient propulsion and performance.

3. Constant Velocity (CV) Joints:

Many drive shafts incorporate Constant Velocity (CV) joints, which help maintain a constant speed and efficient power transmission, even when the driving and driven components are at different angles. CV joints allow for smooth power transfer and minimize vibration or power losses that may occur due to changing operating angles. By maintaining constant velocity, drive shafts contribute to efficient power transmission and improved overall vehicle performance.

4. Lightweight Construction:

Efficient drive shafts are often designed with lightweight materials, such as aluminum or composite materials. Lightweight construction reduces the rotational mass of the drive shaft, which results in lower inertia and improved efficiency. Reduced rotational mass enables the engine to accelerate and decelerate more quickly, allowing for better fuel efficiency and overall vehicle performance.

5. Minimized Friction:

Efficient drive shafts are engineered to minimize frictional losses during power transmission. They incorporate features such as high-quality bearings, low-friction seals, and proper lubrication to reduce energy losses caused by friction. By minimizing friction, drive shafts enhance power transmission efficiency and maximize the available power for propulsion or operating other machinery.

6. Balanced and Vibration-Free Operation:

Drive shafts undergo dynamic balancing during the manufacturing process to ensure smooth and vibration-free operation. Imbalances in the drive shaft can lead to power losses, increased wear, and vibrations that reduce overall efficiency. By balancing the drive shaft, it can spin evenly, minimizing vibrations and optimizing power transmission efficiency.

7. Maintenance and Regular Inspection:

Proper maintenance and regular inspection of drive shafts are essential for maintaining their efficiency. Regular lubrication, inspection of joints and components, and prompt repair or replacement of worn or damaged parts help ensure optimal power transmission efficiency. Well-maintained drive shafts operate with minimal friction, reduced power losses, and improved overall efficiency.

8. Integration with Efficient Transmission Systems:

Drive shafts work in conjunction with efficient transmission systems, such as manual, automatic, or continuously variable transmissions. These transmissions help optimize power delivery and gear ratios based on driving conditions and vehicle speed. By integrating with efficient transmission systems, drive shafts contribute to the overall efficiency of the vehicle propulsion and power transmission system.

9. Aerodynamic Considerations:

In some cases, drive shafts are designed with aerodynamic considerations in mind. Streamlined drive shafts, often used in high-performance or electric vehicles, minimize drag and air resistance to improve overall vehicle efficiency. By reducing aerodynamic drag, drive shafts contribute to the efficient propulsion and power transmission of the vehicle.

10. Optimized Length and Design:

Drive shafts are designed to have optimal lengths and designs to minimize energy losses. Excessive drive shaft length or improper design can introduce additional rotational mass, increase bending stresses, and result in energy losses. By optimizing the length and design, drive shafts maximize power transmission efficiency and contribute to improved overall vehicle efficiency.

Overall, drive shafts contribute to the efficiency of vehicle propulsion and power transmission through effective power transfer, torque conversion, utilization of CV joints, lightweight construction, minimized friction, balanced operation, regular maintenance, integration with efficient transmission systems, aerodynamic considerations, and optimized length and design. By ensuring efficient power delivery and minimizing energy losses, drive shafts play a significant role in enhancing the overall efficiency and performance of vehicles and machinery.

What is a drive shaft and how does it function in vehicles and machinery?

A drive shaft, also known as a propeller shaft or prop shaft, is a mechanical component that plays a critical role in transmitting rotational power from the engine to the wheels or other driven components in vehicles and machinery. It is commonly used in various types of vehicles, including cars, trucks, motorcycles, and agricultural or industrial machinery. Here’s a detailed explanation of what a drive shaft is and how it functions:

1. Definition and Construction: A drive shaft is a cylindrical metal tube that connects the engine or power source to the wheels or driven components. It is typically made of steel or aluminum and consists of one or more tubular sections with universal joints (U-joints) at each end. These U-joints allow for angular movement and compensation of misalignment between the engine/transmission and the driven wheels or components.

2. Power Transmission: The primary function of a drive shaft is to transmit rotational power from the engine or power source to the wheels or driven components. In vehicles, the drive shaft connects the transmission or gearbox output shaft to the differential, which then transfers power to the wheels. In machinery, the drive shaft transfers power from the engine or motor to various driven components such as pumps, generators, or other mechanical systems.

3. Torque and Speed: The drive shaft is responsible for transmitting both torque and rotational speed. Torque is the rotational force generated by the engine or power source, while rotational speed is the number of revolutions per minute (RPM). The drive shaft must be capable of transmitting the required torque without excessive twisting or bending and maintaining the desired rotational speed for efficient operation of the driven components.

4. Flexible Coupling: The U-joints on the drive shaft provide a flexible coupling that allows for angular movement and compensation of misalignment between the engine/transmission and the driven wheels or components. As the suspension system of a vehicle moves or the machinery operates on uneven terrain, the drive shaft can adjust its length and angle to accommodate these movements, ensuring smooth power transmission and preventing damage to the drivetrain components.

5. Length and Balance: The length of the drive shaft is determined by the distance between the engine or power source and the driven wheels or components. It should be appropriately sized to ensure proper power transmission and avoid excessive vibrations or bending. Additionally, the drive shaft is carefully balanced to minimize vibrations and rotational imbalances, which can cause discomfort, reduce efficiency, and lead to premature wear of drivetrain components.

6. Safety Considerations: Drive shafts in vehicles and machinery require proper safety measures. In vehicles, drive shafts are often enclosed within a protective tube or housing to prevent contact with moving parts and reduce the risk of injury in the event of a malfunction or failure. Additionally, safety shields or guards are commonly installed around exposed drive shafts in machinery to protect operators from potential hazards associated with rotating components.

7. Maintenance and Inspection: Regular maintenance and inspection of drive shafts are essential to ensure their proper functioning and longevity. This includes checking for signs of wear, damage, or excessive play in the U-joints, inspecting the drive shaft for any cracks or deformations, and lubricating the U-joints as recommended by the manufacturer. Proper maintenance helps prevent failures, ensures optimal performance, and prolongs the service life of the drive shaft.

In summary, a drive shaft is a mechanical component that transmits rotational power from the engine or power source to the wheels or driven components in vehicles and machinery. It functions by providing a rigid connection between the engine/transmission and the driven wheels or components, while also allowing for angular movement and compensation of misalignment through the use of U-joints. The drive shaft plays a crucial role in power transmission, torque and speed delivery, flexible coupling, length and balance considerations, safety, and maintenance requirements. Its proper functioning is essential for the smooth and efficient operation of vehicles and machinery.

editor by CX 2024-01-18

in Casablanca Morocco sales price shop near me near me shop factory supplier High Efficiency Tractor Mounted Cutting Machine Bx42r Chipper Shredder manufacturer best Cost Custom Cheap wholesaler

Quality and credit are the bases that make a company alive. Services & Top quality controlWe offer comprehensive drawings and offer whenever necessary. Our principal goods are Needle Roller bearings, Cylindrical Roller Bearings, Rod end Bearings, Spherical simple bearings, Monitor roller Bearings for Guideway, Roller Bearings, Combine Bearings for forklifts, H2o Pump Bearings, SNR Vehicle Bearings and all sorts of Spherical Bearings.

Characteristics:

- For 20-fifty HP tractors (15-seventy four kW)

- Disc-operated chipper

- EPT EPTT with double rollers

- EPT feeding control with rollers double rotation: EPTT and reverse

- EPTT cease of EPTT offer from safety

- Discharge hood with 360 deg double adjustment

- Basic safety kit incEPTTd

- 4 rotary knives one stationary knife

- EPT flow velocity management valve

Description:

EPT Duty Chipping EPTT. At the heart of the our BX42R Chipper is an oversize weighty duty rotor and reversible chipping blades. The huge diameter rotor has a more rapidly tip speed for improved chipping action. The hefty-gauge metal retains your momentum to EPTT via tree trunks. The reversible blades are precision lower resource metal, hardened for EPTT-long lasting sharpness.

Flip branches and leaves into a useful source which is ideal for pathwaEPTTand flowerbeds with a FRED Chipper. Chipping is your very best method of lowering huge, uncomfortable branches to a fraction of their dimension, generating dealing with effortless and generating a useful floor cover that assists handle weeds and retain dampness in scorching weather conditions.

There are no belts or pulleEPTTto worry about when you’re in the woods. Immediately linked to your tractor’s PTO, EPTT is transferred straigEPTT into chipping motion. four quot diameter logs are swiftly mulched with the BX42R.

With a PTO EPTTed rotor and EPT feed hopper, branches, limbs and brush are manage fed for constant chipping at maXiHu (West EPT) Dis.mum potential.

EPTnical Technical specs:

FAQ:

Best best made in China – replacement parts – PTO shaft manufacturer & factory Durable pto shaft 1 3/8 6 spline Farm Machine Dq504 50HP 4WD China Garden Wheel Tractor with Canopy with ce certificate top quality low price

We – EPG Team the largest agricultural gearbox and pto manufacturing unit in China with 5 diverse branches. For much more information: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

e39 driveshaft “EPG” touareg generate shaft model 1000 rpm pto shaft measurements rotocultivator pto plastic defend ploughshares john deere f935 pto clutch in changing pto shaft on john deere T.S. jeep xj rear driveshaft total fifty five inch driveshaft lines massey tractor pto shaft created new holland 1411 pto shaft in our manufacturing unit have been analyzed and appraised by the Ministry of Agriculture and have acquired the license of popularizing farm machinery promulgated by the Ministry of Agriculture of the People’s Republic of China. EPG is specialised in design and style, company and sales of agricultural machinery and farm implements, which has an impartial import and export legal rights. Sturdy farm machine DQ504 50HP Four wheel drive China Backyard garden wheel tractor with Canopy

Tractor Primary Functions and Benefits:

one.Geared up renowned manufacturer motor demonstrating advanced capability, reduced fuel usage and large economic efficiency.

2. Streamlined appearance design, gorgeous and generous.

three.Transmission Case adopt meshed change and insert the gearbox interlock system makes the operation a lot more efficiently, dependable and less difficult.

4. Double action clutch with disc spring, execute steadily and easy to work.

five. Completely hydraulic steering method greatly decreased driver’s perform power.

6. Damp disc brake unit, dependable brake performance.

7. Separate injection of hydraulic oil, trustworthy to run.

8. The lifter with force and place adjustment, with dependable lift.

9. Tractor PTO:

PTO in Double pace : 540/a thousand, 760/a thousand, 540/760r/min Optional, For high working performance.

PTO shaft of 6 or 8 spline Optional, adaptable for agricultural equipment of all above the globe.

ten. Complete collection light-weight, ROPS,Sunshade/Canopy, Supporter/Heater/Air-conditioned cabin are all obtainable, for more relaxed driving environment.

Tractor Major specificaiton and Technical parameters:

| Tractor Model | DQ504 |

| Travel sort | 4×4 |

| Engine | |

| Sort of motor | Xinchai 4-Cylinder EPT motor |

| Potential of gasoline tank(L) | 38L |

| Engine power at rated speed | 36.8kw / 50HP |

| Rated velocity (r/min) | 2400 |

| Transmission | |

| Clutch | dry,twin-phase kind |

| PTO velocity | 540/1000rpm or 540/760rpm |

| Equipment change | 8F+4R/8F+8R/12F+12R (Optional) |

| Hydraulic technique | |

| Hydraulic output valve | 2-Way (optional) |

| Three position linkage | |

| Class of 3-level website link | rear, category II |

| Lifting force (at level of 610mm)KN | twelve |

| Technical parameter | |

| Overall size (L x W x H)mm | 3513x1750x2130 |

| Wheel base (mm) | 2040 |

| The smallest clearance (mm) | 325 |

| Front tire | eight.3-20 |

| Rear tire | twelve.4-28/14.9-24 (optional) |

| Optional Configurations | |

| ROPS,Cover(Sunshade),Cabin with Enthusiast/Heater/Air-issue, 2-Team Hydraulic output valve, Front ballast, Rear ballast,Air brake, 8F+8R/12F+12R Shuttle gearshift,Paddy tire, 14.9-24 massive rear tire, Swing attract bar. | |

EPT Manufacutring Line:

DQ504 50HP 4 wheel drive tractor detail demonstrating:

DQ504 50HP 4 wheel drive Tractor packing and Shipping and delivery transporting:

Higher quality Tractor have ISO,CE, PVOC COC, CO, and so forth certificates:

Ideal cost will be quoted for you as quickly as obtain your Requirement !

Best wholesaler made in China – replacement parts – PTO shaft manufacturer & factory Bx42r tractor supply pto slip clutch Wood Splitter with Hydraulic System, Durable Crushing Machine with ce certificate top quality low price

We – EPG Group the greatest agricultural gearbox and pto manufacturing unit in China with 5 different branches. For a lot more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

driver side axle substitution “EPG” 2005 chevy silverado push shaft model pto shear bolts rotocultivator slip clutch for tractor pto ploughshares travel shaft yoke alignment in tractor pto shaft mishaps T.S. walterscheid pto areas overall ford 8n pto shaft assembly lines pto generate shaft restore developed 6852r traxxas in our factory have been analyzed and appraised by the Ministry of Agriculture and have acquired the license of popularizing farm equipment promulgated by the Ministry of Agriculture of the People’s Republic of China. EPG significant production is of farming fifteen-500 horsepower tractor supporting equipment, mechanical cultivation, harvesting equipment and equipment.

Functions:

- For twenty-50 HP tractors (15-seventy four kW)

- Disc-operated chipper

- Hydraulic transmission with double rollers

- Wood feeding handle with rollers double rotation: forward and reverse

- Automated cease of power source from security

- Discharge hood with 360° double adjustment

- Security kit provided

- 4 rotary knives + 1 stationary knife

- Hydraulic circulation pace handle valve

Description:

Large Obligation Chipping Electricity. At the coronary heart of the our BX42R Chipper is an oversize hefty duty rotor and reversible chipping blades. The huge diameter rotor has a faster idea pace for improved chipping action. The weighty-gauge steel keeps your momentum to electricity by way of tree trunks. The reversible blades are precision minimize tool metal, hardened for prolonged-long lasting sharpness.

Turn branches and leaves into a useful useful resource which is EPT for pathways and flowerbeds with a EPT Chipper. Chipping is your greatest technique of lowering large, awkward branches to a fraction of their dimension, producing dealing with effortless and generating a helpful ground protect that helps control weeds and retain moisture in scorching temperature.

There are no belts or pulleys to be concerned about when you’re in the woods. Straight related to your tractor’s PTO, electrical power is transferred straight into chipping motion. 4″ diameter logs are swiftly mulched with the BX42R.

With a PTO run rotor and hydraulic feed hopper, branches, limbs and brush are handle fed for steady chipping at greatest capacity.

Complex Requirements:

FAQ:

Best wholesaler made in China – replacement parts – PTO shaft manufacturer & factory Tractor pto shaft guards Driven Wood Pellet Making Machine Biomass Grass Pellet Mill for Sale with ce certificate top quality low price

We – EPG Team the largest agricultural gearbox and pto manufacturing unit in China with 5 distinct branches. For a lot more details: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

employ pto shaft vehicle travel shaft EPG 1000 rpm pto is collection 8 pto generate shaft specialized john deere rear pto shaft in pto shaft set up style, 2009 f150 drive shaft maker j&r driveshafts and saturn vue push shaft replacement income tacoma generate shaft of agricultural machinery and farm implements, which has an independent import and export rights. Tractor Driven PTO kind Biomass Wood Sawdust Pellet Mill / Pelletizer / Granulator

Characteristics:

Our PTO pellet machine can be driven by diesel engine and electric motor for your options.

Diesel wood pellet machinery is for pressing all kinds of biomass material to be solid pellets which is for burning fuel or animal feed for the size of final pellet can be 6mm,8mm.

The pellet device adopts EPT large-high quality materia EPT and superior coupling shaft push system. The essential parts are made of substantial grad sophisticated alloy metal, which extends the usage daily life 5-7 instances more time.

The concluded items are clean in area and shapely in posture. Its hardness is carefully to European stHangZhourd. Pellet fuel is hassle-free in the approach of producing, packing, storing and transporting as a clean renewable power. This type of Granulation is easy to function and preserve with reduce price tag.

Specificaitons:

| Product | Potential | Dimension | Fat |

| PTO-two hundred | a hundred-one hundred twenty kg/h | five hundred*450*900mm | 150kg |

| PTO-250 | 200-250 kg/h | 550*500*1050mm | 280kg |

| PTO-300 | 250-three hundred kg/h | 600*550*1200mm | 350kg |

| PTO-350 | 300-five hundred kg/h | 650*600*1300mm | 500kg |

Relevant Pellet Machinery:

Best China manufacturer & factory New in Muzaffarnagar India Product OEM Different Type Agricultural Machine Farm Tractor Drive Shaft With high quality best price

With thorough requirments, we can also create your particular developed product. a specialised supplier of a complete range of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Swift Details

- Guarantee:

-

1.5 several years

The organization covering 88,000 square meters, has innovative tools and powerful complex strength, such as the numerical management equipment tools and machining facilities, CAD/CAM system, industrial robotic etc.

- Relevant Industries:

-

Production Plant

- After Warranty Service:

-

On the web assistance

- Local Support Area:

-

none, Italy

- Showroom Place:

-

ITALY

- Type:

-

Shafts

- Place of Origin:Zhejiang, China

- Brand name Title:

-

OEM

- certification:

-

CE

- Material:

-

Metallic

- Perform:

-

Power transmission

- Processing of yoke:

-

Forging

- Processing of tube:

-

Cold drawn.

- Style:

-

Customized.

- Certification:

-

CE Certificate.

Worm gears are usually created by hobbing with a hob or cutting instrument extremely related to the worm that the equipment mates with. The worm might be turned, hobbed, milled, or ground.

Provide Capacity

- Supply Capacity:

- 10000 Piece/Parts for every Thirty day period

Packaging & Supply

- Packaging Information

- carton/iron crate

- Port

- ningbo or shanghai

Online Customization

Solution Details

Item Info

PTO Shaft

The power take-off (PTO) is a innovative system, enabling implements to draw strength from the motor and transmit it to anoOnce the PTO has started to energy the attachment, steadily increase the throttle until you reach the running speed. The common running RPM (revolutions for each minute) for a tractor mounted PTO is 540 RPM, despite the fact that there are tractor types that rev higher. Often refer to your particular tractor model for recommendations prior to initial-time use.ther software. It operates as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The electrical power get-off shaft (PTO shaft) is a crucial element, created and manufactured for continuous large-obligation use. A excellent PTO shaft must be powerful adequate to bear the torsion and shear pressure and reduce vibration.

Setforge, the forging subsidiary of Ever-Electrical power Team, manufactures cold extruded PTO shafts for all varieties of agriculture vehicles. Our PTO shafts supply fantastic dependability and toughness during everyday use.

EP Group has been internationally identified as a reputable worldwide provider. Our point out-of-the-artwork producing process and seasoned engineers make certain the prime-good quality of all Farinia parts.

| Following Warranty Services | Online video technical assist |

| Relevant Industries | Producing Plant |

| Nearby Support Area | Italy |

| Showroom Location | Italy |

| Warranty | 1.5 several years |

| Type | Shafts |

| Area of Origin | China |

| China | Zhejiang |

| Brand Name | EPG |

| certificate | CE |

| Material | Steel |

| Perform | Electricity transmission |

| Processing of yoke | Forging |

| Processing of tube | Cold drawn. |

| Design | Custom-made. |

| Certificate | CE Certification. |

Product Exhibit

Item Display

PTO Drive Line Gen …

Agricultural Gearb …

Agricultural Gearb …

CompanyInfo

Company Profile

At any time-Energy Team

EPG have higher-tech machinery and test equipment. We can make world course large precision items.

Certifications

Certifications

Cargo & Payment

Our Rewards

A: Your inquiry associated to our goods or prices will be replied in 24 hours.

B: Safety of your revenue location, suggestions of design and style and all your personal data.

C: Best high quality and aggressive cost.

……

faq

FAQ

1) How can I location buy?

A: You can speak to us by e mail about your order particulars, or area order on line.

2) How can I shell out you?

A: After you validate our PI, we will ask for you to spend. T/T (HSBC financial institution) and Paypal, Western Union are the most normal ways we are using.

……